Test Results

- Lifetest comparison of Particle Interconnect vs. commonly available sockets

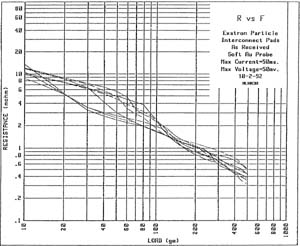

- Contact resistance (milli-Ohm) vs. holddown force (gram-force)

- Battery discharge rate [0.200 Amp]

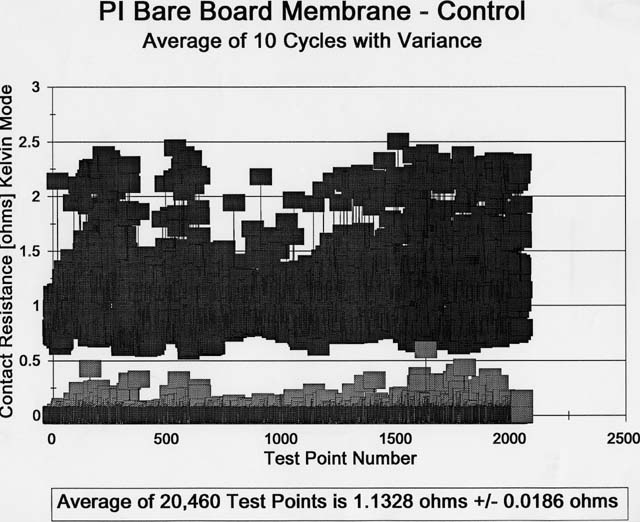

- Particle Interconnect bare board membrane test fixture test results

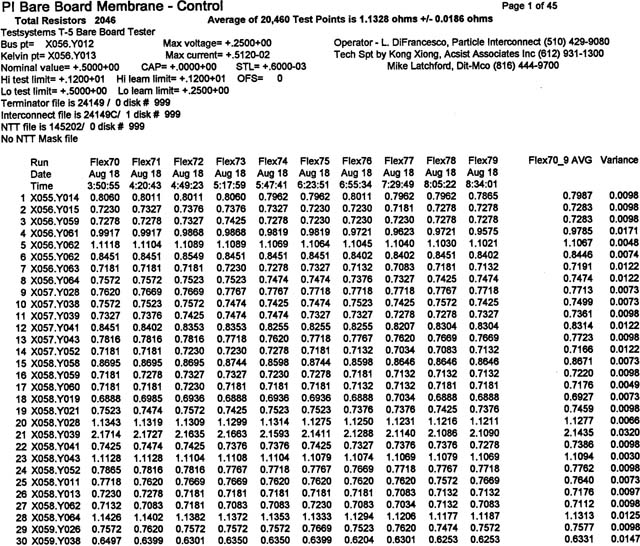

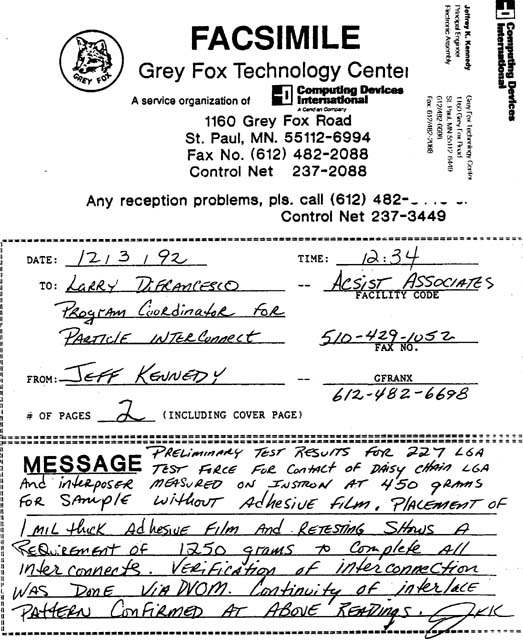

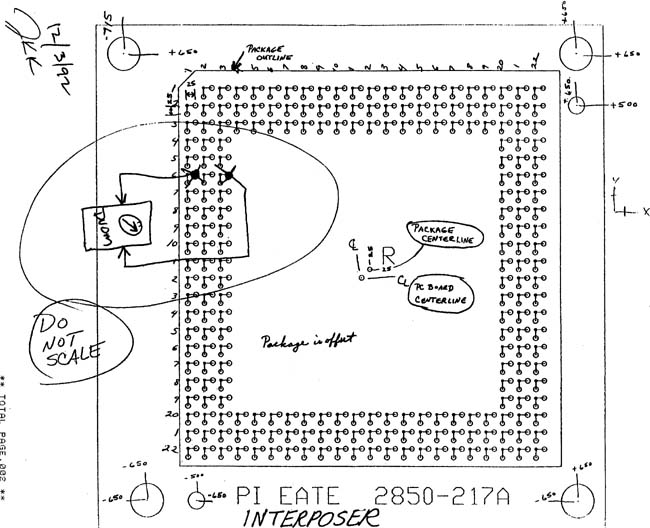

- Test results for Particle Interconnect to punch through adhesive film

- MIL-STD-810F summary for Particle Interconnect

- SEM, FIB, AFM pictures of metal

- Scanning electron microscope pictures of PI

- Optical microscope pictures of PI

- Standard wiping contact spalling

- TDR, S parameter, Eye diagram

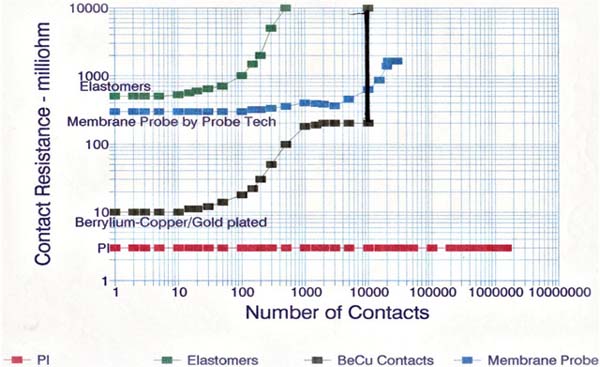

Lifetest comparison of Particle Interconnect vs. other sockets

Tested to failure.

This graph illustrates the exceptionally long remate life the Particle Interconnect coating provides a contact. Since the non-wiping action of the particles does very little damage to the mating surface, contacts last for 1,000,000 insertions or more. While this number is higher than the most applications require, it does testify to the robustness of connections using Particle Interconnect coatings.

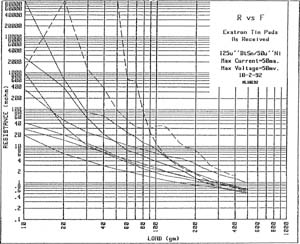

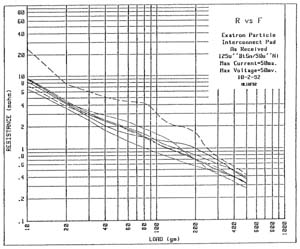

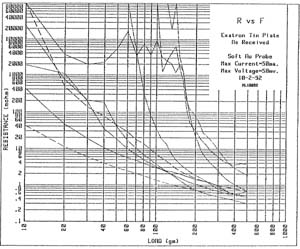

Contact resistance (milli-Ohm) vs. holddown force (gram-force)

Courtesy of Amp

These graphs show how Particle Interconnect coated contacts compare to traditional scrubing contact surfaces as regard to contact force and resistance. They illustrate the exceptionally low contact force of Particle Interconnect, showing this force to be at the test limit of 10 grams.

More importantly, the graphs show how consistently Particle Interconnect coatings perform between remate cycles. While tin and gold plated contacts 40 to 100 gram range initially, this performance was inconsistent and tended to degrade between remates because of oxide growth.

0.25" diameter hemispherical probes vs. 63/37 tin-lead coated surface.

| Bright tin probe vs. control (no PI) | Bright tin probe vs. 20-25 μ PI |

|

|

|

. 0.010" BeCu, 0.250" Ni, 0.150" SnPb. . 20 to 80,000+ milli-Ohms, 1 to 9 remates. . No scrubbing action. |

. 0.010" BeCu, 0.250" Ni + PI, 0.150" SnPb. . 6 to 9 milli-Ohms (one ignored), 1 to 6 remates. . No scrubbing action against PI. |

| Gold Probe vs. Control (no PI) | Gold probe vs. 20-25 μ PI |

|

|

|

. 0.010" BeCu; 0.250" Ni; 0.150" SnPb. . 20 to 80,000+ milli-Ohms, 1 to 9 remates. . No scrubing action. |

. 0.010" BeCu; 0.250" Ni + PI; 0.150" SnPb. . 8 to 14 milli-Ohms, 1 to 8 remates. . No scrubbing action against PI. |

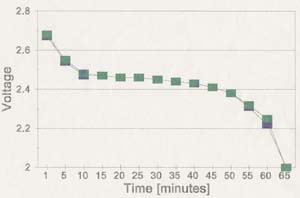

Battery discharge rate

Particle Interconnect vs. 4 weld spots, 0.200 Amp current.

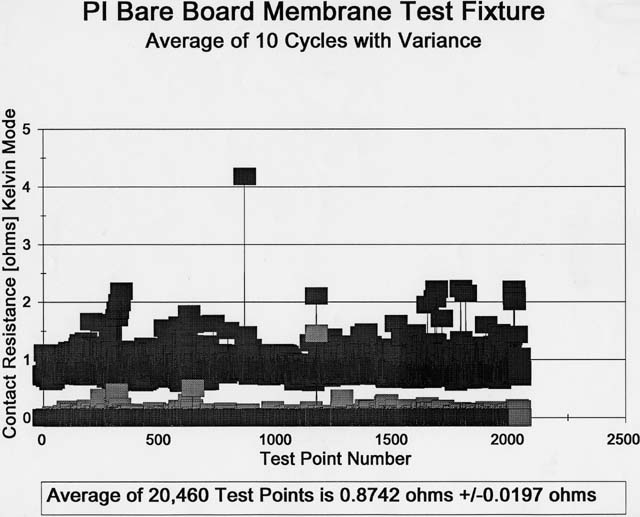

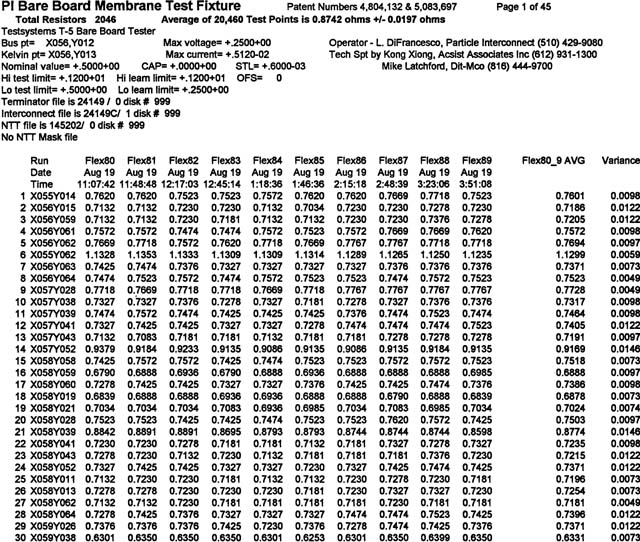

Particle Interconnect bare board membrane test fixture test results

Compared to control on test system T-5.

Using vacuum for holddown.

Test results for Particle Interconnect to punch through adhesive film

Jeff Kennedy

Grey Fox Technology Center

MIL-STD-810F summary for Particle Interconnect

Climatic Category

| Required Test Values | PI Tested Values |

| Hot 32-49 C (90-120 F), solar radiation 1120 W/m2, relative humidity 8-3% | 100 W halogen lamp 5 hours |

| Humid tropic zone 26-35 C (78-95 F), solar radiation 970 W/m2, relative humidity 100-74% | |

| Severe cold -51 C (-60 F), solar radiation negilible, relative humidity saturated |

Part Two - Laboratory Test Methods

| 500 | Low Pressure (Altitude) | 500.4-1 - 500.4-8 |

| 501 | High Temperature | 501.4-1 - 501.4-12 |

| 502 | Low Temperature | 502.4-1 - 502.4-10 |

| 503 | Temperature Shock | 503.4-1 - 503.4-10 |

| 504 | Contamination by Fluids | 504-1 - 504A-2 |

| 505 | Solar Radiation (Sunshine) | 505.4-1 - 505.4A-8 |

| 506 | Rain | 506.4-1 - 506.4-12 |

| 507 | Humidity | 507.4-1 - 507.4A-2 |

| 508 | Fungus | 508.5-1 - 508.5A-2 |

| 509 | Salt Fog | 509.4-1 - 509.4-10 |

| 510 | Sand and Dust | 510.4-1 - 510.4-14 |

| 511 | Explosive Atmosphere | 511.4-1 - 511.4-8 |

| 512 | Immersion | 512.4-1 - 512.4-8 |

| 513 | Acceleration | 513.5-1- 513.5-12 |

| 514 | Vibration | 514.5-i - 514.5C-16 |

| 515 | Acoustic Noise | 515.5-i - 515.5B-2 |

| 516 | Shock | 516.5-i - 516.5C-4 |

| 517 | Pyroshock | 517-1 - 517-24 |

| 518 | Acidic Atmosphere | 518-1 - 518-6 |

| 519 | Gunfire | 519.5-i - 519.5D-10 |

| 520 | Temperature, Humidity, Vibration, and Altitude | 520.2-1 - 520.2A-10 |

| 521 | Icing/Freezing Rain | 521.2-1 - 521.2-8 |

| 522 | Ballistic Shock | 522-1 - 522-14 |

| 523 | Vibro-Acoustic/Temperature | 523.2-1 - 523.2A-8 |

| Required Test Values | PI Tested Values |

|

Method 503.4: "... apply three shocks or more at each condition ... Transfer the test item between the two environments (high and low temperatures) as rapidly as possible but in no more than five minutes ..."

Maximum climatic categories: Hot 49 C, severe cold -51 C. |

-60 to 150 C thermal shock 5 cycles 1 min/cycle. Ambient outside air temperature of -60 C is equivalent to 13 Km (43,000 ft). |

| Method 520.2: Worse cases are ambient outside air temperature of -82 C (-116 F) at 16 Km (52,500'), and cold ground soak temperature of 71 C (160 F) | |

| Method 513.5: Manned aerospace vehicles 6-12 g | |

| Method 516.5: Crash hazard 40 g, ground equipment 75 g | |

| Method 516.5: Tansit drop test of man-portable under 100 lbs, 122 cm (48") height of drop. Drop on each face, edge, and corner; total of 26 drops. | |

| Method 519.5: Worse case gun fire pulse amplitude 130 g's @ 1,781.8 Hz (GAU-8/A, 30 mm cannon) | |

| Method 522: "... Ballistic shock is a high-level shock ... from the impact of projectiles or ordnance on armored combat vehicles [without penetration] ... There is no intent here to define the actual shock environment for specific vehicles. ..." |

12 gauge shot gun into water, sand, and concrete.

~1000+ g impact at 60 mph, ~50,000+ g cannon launch. |