Standard Wiping Contact Spalling

Pictures

Standard wiping contact cross section after spalling

Metal removed by wiping.

|

|

|

|

|

Metal fracture.

Standard wiping contact cross section without spalling

|

|

|

|

|

|

|

|

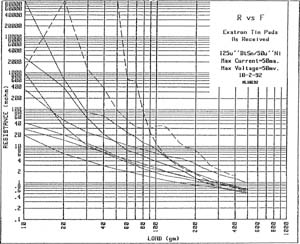

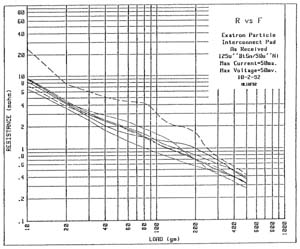

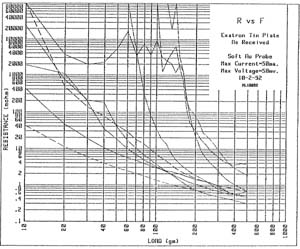

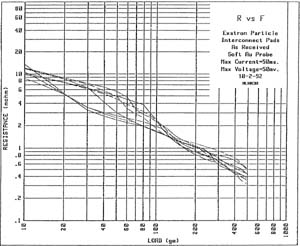

Resistance change

Contact resistance (milli-Ohm) vs. holddown force (gram-force)

Courtesy of Amp

These graphs show how Particle Interconnect coated contacts compare to traditional scrubing contact surfaces as regard to contact force and resistance. They illustrate the exceptionally low contact force of Particle Interconnect, showing this force to be at the test limit of 10 grams.

More importantly, the graphs show how consistently Particle Interconnect coatings perform between remate cycles. While tin and gold plated contacts 40 to 100 gram range initially, this performance was inconsistent and tended to degrade between remates because of oxide growth.

0.25" diameter hemispherical probes vs. 63/37 tin-lead coated surface.

| Bright tin probe vs. control (no PI) | Bright tin probe vs. 20-25 μ PI |

|

|

|

. 0.010" BeCu, 0.250" Ni, 0.150" SnPb. . 20 to 80,000+ milli-Ohms, 1 to 9 remates. . No scrubbing action. |

. 0.010" BeCu, 0.250" Ni + PI, 0.150" SnPb. . 6 to 9 milli-Ohms (one ignored), 1 to 6 remates. . No scrubbing action against PI. |

| Gold Probe vs. Control (no PI) | Gold probe vs. 20-25 μ PI |

|

|

|

. 0.010" BeCu; 0.250" Ni; 0.150" SnPb. . 20 to 80,000+ milli-Ohms, 1 to 9 remates. . No scrubing action. |

. 0.010" BeCu; 0.250" Ni + PI; 0.150" SnPb. . 8 to 14 milli-Ohms, 1 to 8 remates. . No scrubbing action against PI. |